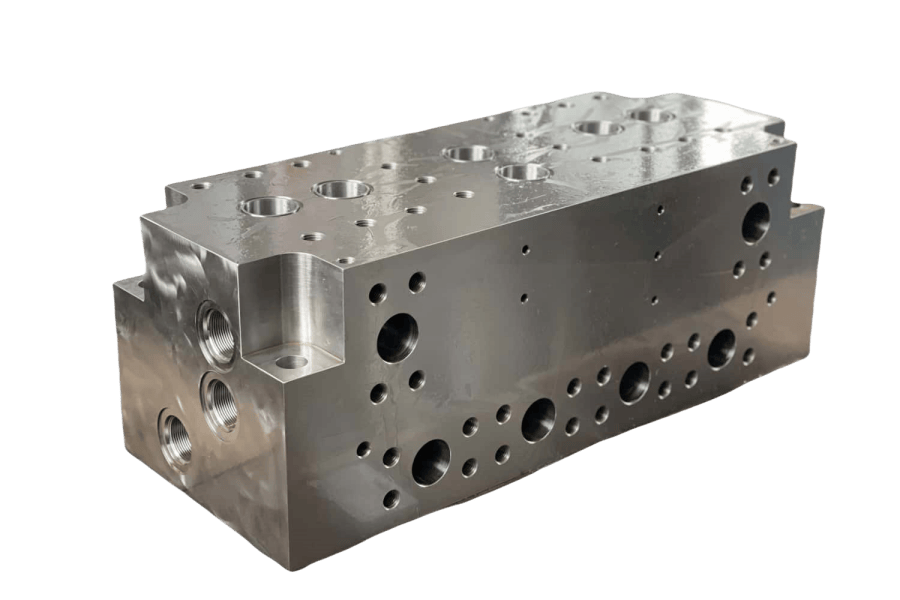

Purchasing CNC machining parts from China can offer several benefits, including cost-effectiveness and a wide variety of options. However, it’s essential to take precautions to ensure quality and reliability. Here are some crucial steps to consider when sourcing CNC machining parts from China:

Research and Background Check

Before engaging with any supplier, conduct thorough research and background checks. Look for reviews, ratings, and testimonials from other customers. Verify the supplier’s credibility and reputation in the industry.

Verify Supplier Credentials

Ensure that the supplier is properly licensed and certified to manufacture CNC machining parts. Check for relevant certifications and quality standards compliance, such as ISO certifications.

Request Samples

Requesting samples is crucial to assess the quality of the CNC machining parts. Evaluate the samples for accuracy, precision, and surface finish. Compare samples from different suppliers to make an informed decision.

Discuss Specifications Clearly

Communicate your requirements and specifications clearly with the supplier. Provide detailed drawings, CAD files, or technical specifications to avoid misunderstandings. Discuss tolerances, materials, and surface finishes upfront.

Ensure Quality Control Measures

Inquire about the supplier’s quality control measures and inspection processes. Ensure that they have stringent quality checks in place throughout the manufacturing process. Ask for documentation and certificates to verify quality standards.

Consider Communication and Language Barriers

Be mindful of potential communication barriers due to language differences. Choose suppliers who have proficient English-speaking staff or utilize translation services if necessary. Effective communication is essential for successful collaboration.

Comparing Prices and Quotations

Obtain quotations from multiple suppliers and compare prices carefully. Consider factors such as material costs, machining complexity, and additional services included. Negotiate terms to secure the best possible price without compromising quality.

Understanding Manufacturing Processes

Gain an understanding of the different machining techniques and processes involved in producing CNC machining parts. Familiarize yourself with the materials commonly used and their properties to make informed decisions.

Quality Assurance and Inspection

Implement stringent quality assurance measures, including pre-production inspections and final product inspections. Conduct on-site visits or enlist the services of third-party inspection agencies to ensure compliance with quality standards.

Packaging and Shipping Considerations

Discuss packaging requirements and shipping methods with the supplier. Ensure that the parts are adequately packaged to prevent damage during transit. Consider factors such as shipping costs, lead times, and import/export regulations.

Dealing with Language and Cultural Differences

Be mindful of language and cultural differences when communicating with Chinese suppliers. Use clear and concise language, and avoid slang or colloquialisms that may be misunderstood. Respect cultural norms and customs in business interactions.

Handling Payment Transactions Securely

Choose secure payment methods to minimize the risk of fraud or financial loss. Consider using escrow services or letters of credit for larger transactions. Verify banking details and confirm the legitimacy of payment requests.

After-sales Support and Warranty

Inquire about the supplier’s after-sales support services and warranty policies. Ensure that they offer prompt assistance in case of any issues or concerns with the CNC machining parts. Clarify warranty terms and conditions upfront.

Building Long-term Relationships with Suppliers

Invest in building strong and mutually beneficial relationships with Chinese suppliers. Foster trust and reliability through open communication and consistent collaboration. Provide feedback and reviews to help improve future transactions.

Addressing Intellectual Property Concerns

Protect your intellectual property rights when sourcing CNC machining parts from China. Implement confidentiality agreements and non-disclosure agreements to safeguard designs and innovations. Seek legal advice if necessary to ensure compliance with intellectual property laws.

Conclusion

Purchasing CNC machining parts from China can be a cost-effective solution for businesses. However, it’s essential to take precautions to ensure quality, reliability, and compliance with standards. By following these precautions and guidelines, businesses can mitigate risks and maximize the benefits of sourcing from China.

FAQs (Frequently Asked Questions)

- Are CNC machining parts from China of good quality?

- While quality can vary among suppliers, many Chinese manufacturers produce high-quality CNC machining parts. It’s crucial to conduct thorough research and inspections to ensure quality standards are met.

- How can I ensure timely delivery of CNC machining parts from China?

- Communicate clearly with the supplier about delivery timelines and expectations. Monitor production progress closely and address any delays promptly to ensure timely delivery.

- What payment methods are commonly used when purchasing CNC machining parts from China?

- Common payment methods include bank transfers, PayPal, letters of credit, and escrow services. Choose a secure payment method that offers protection for both parties.

- What should I do if I encounter language barriers when dealing with Chinese suppliers?

- Utilize translation services or hire a bilingual intermediary to facilitate communication. Ensure that important information is conveyed accurately to avoid misunderstandings.

- How can I protect my intellectual property when sourcing CNC machining parts from China?

- Implement confidentiality agreements and non-disclosure agreements to protect your designs and innovations. Seek legal advice to ensure compliance with intellectual property laws and regulations.